The cement we use is Portland cement, a form of limestone.

Cement is used to encapsulate the steel mesh in thin layers forming the walls of the tanks. This method utilizes the compressive strength of cement and tensile strength for a marriage of unequal quality.

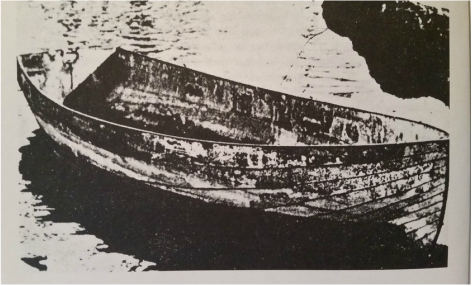

Ferrocement was first used back in the 1850s, by the great French architect Henri Labrouste, a Boulogne gardener Joseph Monier and a country gentleman named Jean-Louis Lambot. They made plaster vaults, flower pots, doors and boats. In 1876 mechanical engineer W.E. Ward built a ferrocement house in Port Chester, New York which is still in good condition!

| The short modular sections allow for an easier casting/curing process and make it much easier to move the sections around. Once cured, we roll them on our trailer and right into your yard where we stack them together, then add a lid. This way we don't need big cranes or a lot of space for installation. |

RSS Feed

RSS Feed